Exploring the Different Types of Rolled Roofing: Your Complete Guide

If you’re seeking a budget-friendly roofing solution for a low-slope or flat roof, understanding the different types of rolled roofing can help you make an informed choice. This article will examine various rolled roofing materials, their uses, benefits, and ideal applications.

Key Takeaways

Rolled roofing is an affordable and flexible choice suitable for low-slope or flat roofs, with a lifespan of 5 to 10 years.

Common types of rolled roofing include asphalt roll, rubber, modified bitumen, EPDM, and TPO, each with its own benefits and applications.

Proper installation and maintenance are essential for maximizing the performance and durability of rolled roofing, which is suitable for small structures and temporary roofing projects.

Understanding Rolled Roofing

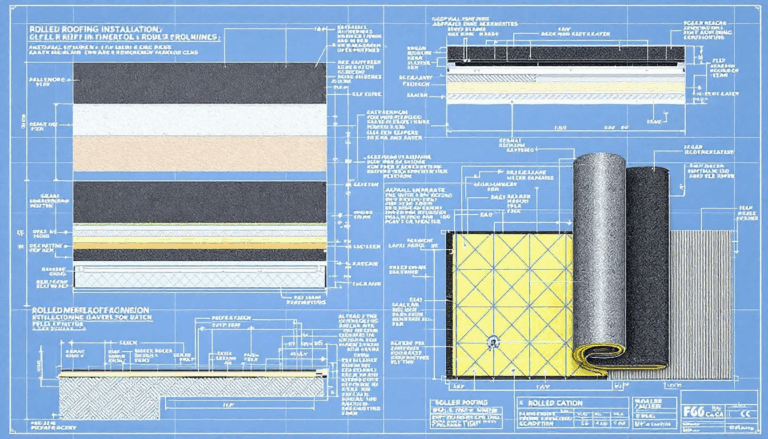

Rolled roofing, often called roll-out roofing, is made from materials like rubber, polymers, or asphalt. It is known for its versatility and affordability. Key features of rolled roofing include:

Affordability: it is much less expensive than other roofing styles.

Lifespan: usually lasts between 5 and 10 years.

Ideal uses: suitable for budget re-roofing or temporary tasks.

Despite its affordability, rolled roofing is often viewed as less durable than traditional options like asphalt shingles. This highlights the importance of considering local climate conditions for effective, cost-efficient roofing.

Rolled roofing is primarily used for low-slope or flat roofs. It is commonly seen on small structures like sheds and garages. The installation is simple and quick, making it easy to apply on existing buildings during re-roofing. With this basic knowledge, let’s explore the different types of rolled roofing materials available for low-slope roof applications.

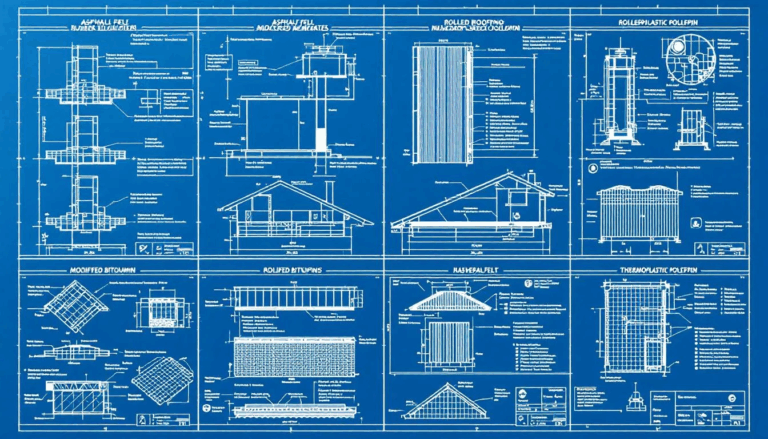

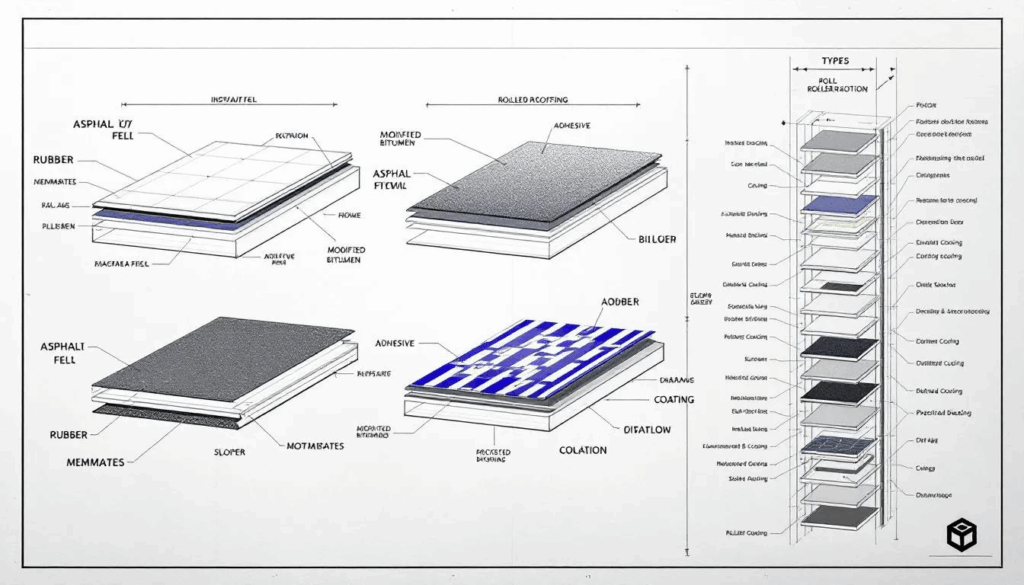

Popular Types of Rolled Roofing Materials

Rolled roofing comes in different types, each offering unique benefits and uses. The most common options include asphalt roll roofing, rubber rolled roofing, modified bitumen roofing, and mineral-surfaced roll roofing. These materials are especially suitable for low-slope and flat roofs, making them perfect for sheds, garages, and similar buildings.

Overall, rolled roofing offer a versatile solution for various roofing needs, balancing cost-effective roofing material and performance effectively, unlike other roofing materials. Mineral-surfaced asphalt has the shortest lifespan and is the least durable among rolled roofing.

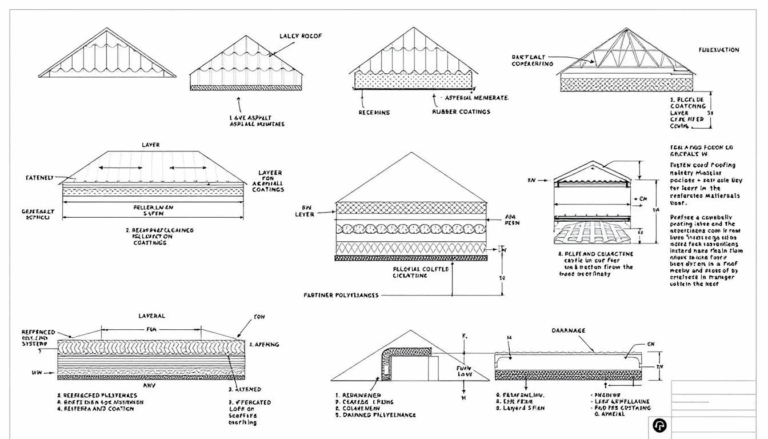

Asphalt Roll Roofing

Asphalt roll roofing comes in various colors and thicknesses, making it versatile enough to suit different aesthetic tastes. Most often used for low-slope structures, it requires less labor to install compared to asphalt shingles. This makes it a practical choice for those who need a quick roofing option without sacrificing too much durability. An asphalt roof can be an excellent choice for such needs.

Typical applications of asphalt roll roofing include roofs of sheds, porches, and garages. Its ease of installation and affordability make it an excellent option for small roofing projects. A good installation method prevents leaks and maximizes lifespan and performance. The cost of rolled roofing varies significantly, with mineral-surfaced asphalt being the cheapest option.

Rubber Rolled Roofing

Rubber-rolled roofing is crafted from recycled tires and a blend of other materials, making it a sturdy and eco-friendly choice. Key points about this type of roofing include:

It is especially advantageous for commercial flat roofs, where its durability and flexibility are greatly appreciated.

It can usually be bought at home improvement stores like Home Depot and Lowe’s.

It is seen as cost-effective because it is cheaper than all other rolled roofing.

Rubber rolled roofing’s main advantage is its weather resistance, making it suitable for a wide range of climates. It creates a watertight seal, ensuring your roof stays intact even during extreme weather. This makes it a dependable choice for those seeking a durable roofing solution at an affordable price.

Modified Bitumen Roofing

Modified bitumen roll roofing, commonly called mod bit, is mainly made from bitumen (asphalt). It provides increased durability, with an average lifespan of about 20 years, making it a long-term investment for various uses. This type of roofing is ideal for low-slope and flat roofs, which are suitable for both residential and commercial buildings.

Installing modified bitumen roofing generally involves self-adhesive sheets, which can be more challenging to install and repair than other roofing types. However, its increased durability and longer lifespan make it a valuable option for those looking for a strong roofing solution.

Specialized Rolled Roofing Options

Specialized rolled roofing meets unique needs and applications. EPDM and TPO roofing enhance longevity and performance for specific applications.

These specialized materials are designed to meet specific performance requirements and address unique needs such as extreme weather conditions.

EPDM Rolled Roofing

EPDM rolled roofing, or Ethylene Propylene Diene Monomer, is a type of synthetic rubber roofing known for its durability and UV resistance. One of the primary benefits of EPDM roofing is its long lifespan, which can exceed 30 years with proper maintenance. This makes it an excellent choice for those looking for a long-term roofing solution.

EPDM roofing is highly resistant to UV rays and extreme weather, making it suitable for a wide range of climates. It is frequently used in commercial roofs, residential homes, and retrofit projects due to its versatility. Its durability and resistance make it a dependable choice for different roofing needs.

TPO Rolled Roofing

TPO rolled roofing is made from a blend of polypropylene and ethylene propylene, and is known for its durability and longevity. TPO typically lasts 20-30 years and is also known for energy efficiency. This type of roofing is commonly used for commercial buildings with flat roofs because it is cost-effective and resistant to punctures. Its strong seam performance, enhanced by hot-air welding, makes it resistant to leaks and severe weather.

TPO is a fully recyclable roofing option with several advantages:

Available in multiple colors, allowing for design versatility while minimizing environmental impact

Durable

Cost-effective

Environmentally beneficial qualities make TPO rolled roofing popular for commercial use.

Choosing the Right Rolled Roofing for Your Project

Selecting the right rolled roofing material for your project involves considering specific performance requirements and conditions. Specialized rolled roofing types are designed to address unique needs such as extreme weather conditions. For harsh weather areas, EPDM or TPO offers enhanced durability and weather resistance.

Rolled roofing is often selected for temporary roofing jobs because of its affordability and easy installation. Assessing long-term maintenance and specific project requirements helps in choosing the best option.

Whether you’re looking for a quick roofing solution or a long-term investment, the variety of rolled roofing types available ensures there’s an option to meet your needs.

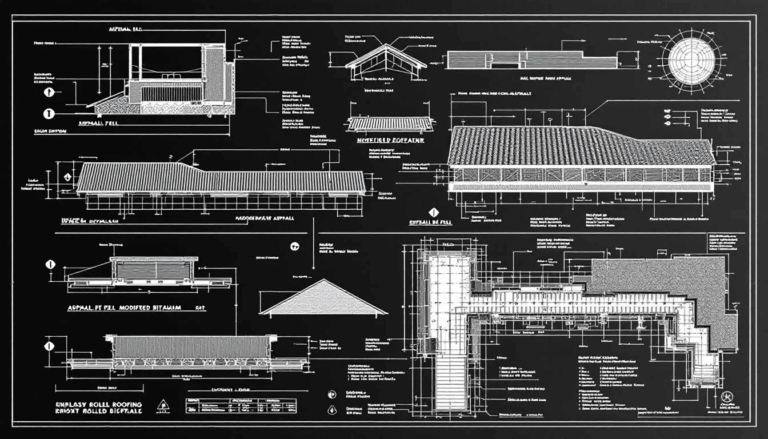

Installation Process for Rolled Roofing

Installing rolled roofing requires several necessary steps to ensure good adhesion and longevity. Before starting, it’s essential to thoroughly clean the roof to remove debris and promote proper sticking. Using a chalk line for measurement helps create a straight edge for accurately laying out the rolled roofing.

The installation procedure usually includes:

Laying roofing cement

Rolling out the material

Cutting it to size

Securing it with roofing nails placed at intervals of about 10 inches

Completing the DIY installation method

It’s worth noting that modified bitumen roofing frequently employs self-adhesive sheets, making installation easier.

Trimming excess rolled roofing at the edges is necessary to create a clean, finished appearance. Applying roofing cement gradually is crucial to forming a strong bond between the roofing material and the surface.

Maintenance Tips for Rolled Roofing

Proper maintenance of rolled roofing can significantly extend its lifespan and ensure optimal performance. It’s recommended to inspect for blisters and cracks regularly to catch issues early. Sealing seams is crucial to preventing water infiltration and keeping the roofing watertight.

To maintain your roofing surface:

Keep the roof surface free of debris to reduce moisture buildup, which can cause long-term damage.

Avoid walking on rolled roofing unless necessary, as foot traffic can cause damage.

Re-seal seams and nail heads every few years to help maintain the integrity of the roofing.

Proper maintenance ensures that rolled roofing provides adequate protection for your property.

Cost Considerations for Rolled Roofing Projects

Today, higher costs significantly influence your projects:

Rolled roofing costs between $1.50 and $2.50 per square foot on average.

For a typical 1,200-square-foot roof, the total cost to apply rolled roofing is about $1,500.

For those opting for a DIY approach, the installation can be accomplished for less than $1 per square foot.

Hiring professionals to install rolled roofing typically costs between $2,500 and $4,800, including installation costs and labor costs. Factors influencing rolled roofing costs include the roof’s size, slope, and type of materials used.

The lifespan of different rolled roofing affects the project’s cost-effectiveness. While rolled roofing is generally less expensive than other roofing options, its shorter lifespan compared to other materials with limited lifespans can affect its resale value, as it may be perceived as a lower-quality option.

Pros and Cons of Rolled Roofing

Rolled roofing offers several benefits, including cost-effectiveness, ease of installation, and light weight. Its affordability and simplicity of installation make it a popular choice for home and business owners, and of course, contractors.

Despite its benefits, rolled roofing is less durable than traditional materials like asphalt shingles and may require more frequent repairs and replacements. Additionally, rolled roofing is susceptible to cracking, tearing, and leaking, which affects its overall durability. It is more prone to durability issues in extreme temperatures. Rolled roofing typically lasts only 5 to 8 years, which is shorter than that of many other roofing materials.

It is usually not suitable for steep roofs and might not be the best option for residential homes due to questions about appearance, durability, and performance. In addition, rolled roofing lacks the durability and aesthetic appeal of traditional shingles. Rolled roofing is limited in color choices and lacks design variety compared to other roofing materials. Despite these limits, rolled roofing offers a good balance of cost and performance for several applications.

Ideal Applications for Rolled Roofing

Rolled roofing is commonly used on small structures like sheds, garages, and other outbuildings. Ideal structures for rolled roofs include:

Sheds

Porches

Garages

Storage units: This roofing type is ideal for properties with flat or low-slope roofs where traditional roofing options may not be effective.

In commercial settings, rolled roofing is popular for roofs because it is affordable and easy to install. It also provides a practical solution for temporary roofing jobs or projects with limited budgets, including various commercial uses. The flat roof option is especially helpful in these cases.

Rolled roofing is not recommended for high-end residential properties or steep-pitched roofs due to its limited lifespan and aesthetic drawbacks. However, rolled roofing can be suitable for temporary roofing needs, such as covering a roof damaged by a storm or during construction projects.

Overall, rolled roofing provides a versatile solution for different roofing requirements and is commonly used on low-slope roofs, where traditional shingles may not be suitable due to water runoff issues.

Summary

In summary, rolled roofing offers a cost-effective and versatile solution for a variety of roofing needs. This guide has covered all essential aspects, from understanding the different types of rolled roofing materials to choosing the right one for your project. Whether you need a quick roofing fix or a long-term investment, rolled roofing provides options that effectively balance cost and performance. By following proper installation and maintenance practices, you can ensure your rolled roofing offers reliable protection for years. Ready to begin your next roofing project? Rolled roofing may be the perfect choice for you.

Frequently Asked Questions

What is rolled roofing made of?

Rolled roofing is mainly composed of materials like rubber, polymers, or asphalt, making it a flexible and budget-friendly choice for roofing projects.

How long does rolled roofing last?

Rolled roofing typically lasts between 5 and 10 years, depending on material quality and environmental conditions. Proper installation and maintenance can help extend its lifespan.

Can rolled roofing be used on steep roofs?

Rolled roofing is not suitable for steep roofs because it works best on low-slope structures. For steeper slopes, look into other roofing options that offer better performance.

What are the main types of rolled roofing materials?

The main types of materials are asphalt roll roofing, rubber roll roofing, and modified bitumen roofing. Each type provides unique benefits tailored for different roofing needs.

How much does it cost to install rolled roofing?

Installing rolled roofing usually costs between $1.50 and $2.50 per square foot, and choosing a DIY installation can further cut costs.